You don’t need to pay a lot to keep your engine in tiptop condition. With the experienced service team from Boeaman ASIA. You can be sure that your engines are in good hands. We have a team of very experienced engineers with more than 15 years of experience with engine makers.

Troubleshooting

We are the experts for 2 Stroke main engines; especially on the MAN B&W 2 stroke engines including ME-B, ME-C, MC and MC-C. Our engineering team consists of Superintendent Engineers and Mechanics with either sea-going experience and / or ex-engine maker backgrounds. They are fully trained and qualified in troubleshooting, problem-solving and repairs.

Pre- Docking Inspection

Your vessel can now go in to dry docking with you fully aware of the cost involved. With our DMA pre-docking inspection, you can now (1) better prevent any unnecessary extension of docking period due to unforeseen issues, (2) have a better budgeting of the repair cost and spare parts cost and (3) have a better planning thus higher efficiency which will lead to lower docking charges.

We will provide you with a list of proposed job scope and spare parts required together with our offer to ease your workload for docking preparation.

What you will receive from us:

- Engine condition report

- List of proposed job scope

- List of proposed required spare parts (for engine and Turbocharger)

- Our offer for carrying out the service and supplying of O.E.M. spare parts

Docking Supervision

You can now focus on other aspect of docking when you engage us to carry out supervision work for all your engine related jobs during docking. We will supply one engineer to carry out supervision of the yard fitters when overhauling your engine. This is a more economical solution to ensure that works are carrying out properly and professionally no matter which shipyard you choose.

Our engineers’ profile specializes on the 2-stroke engines especially on MAN B&W ME-B, ME-C, MC and MC-C.

And most importantly, our Engineers are readily to travel out to most destinations within short notices including Malaysia, Indonesia, Thailand, Myanmar, India, Dubai, China and many more countries.

Unit Overhauling

When time is a constrain but you need to ensure serviceability of your engine whenever your vessel call Singapore or Malaysia. We have a full service team which includes engineer and mechanics to carry out unit overhauling onboard while your cargo operations is taking place thus reducing unnecessary downtime for your operations.

Our scope of work includes:

- Removal of cylinder cover from existing unit.

- Inspection of combustion space, injector spray path etc.

- Renewal of cylinder water guide jacket O-ring.

- Removal of wear-ridge on cylinder liner, clean combustion area and lift up piston.

- Cylinder liner surface to be cleaned and inspected.

- Piston crown to be de-carbonized and calibrated on ring grooves.

- Piston skirt to be inspected of scuffing marks.

- Re-installation of new sets of piston rings.

- Overhauled piston to be fitted back to unit.

Additional works (Subjected to cylinder conditions)

- Renewal of cylinder liner due to wear / damage.

- Renewal of piston crown / skirt with new spare onboard while using back the existing piston rod.

- Overhauling of stuffing box

Bearing Inspection and Renewal

Observed any abnormalities during your engine operations? Need to satisfy the classification society’s requirement? We also carry out bearing inspection and renewal whenever you require.

Our scope of service includes:

- Crankpin bearing inspection

- Crankpin bearing renewal

- Crosshead bearing inspection

- Crosshead bearing renewal

- Main bearing inspection

- Main bearing renewal

Scavenging Port Inspection

Scavenging port inspection is a low expense inspection which provides useful information about condition of

cylinders, pistons, skirts, rods and ring. All you need is an engineer from us onboard together with the

assistance of your ship crew to carry out the necessary inspection.

Our scope of work includes:

- Checking of cylinder liner condition.

- Checking of piston rings condition.

- Checking of piston crown condition.

- Checking of scavenge port condition.

- Checking of piston rod and skirt condition.

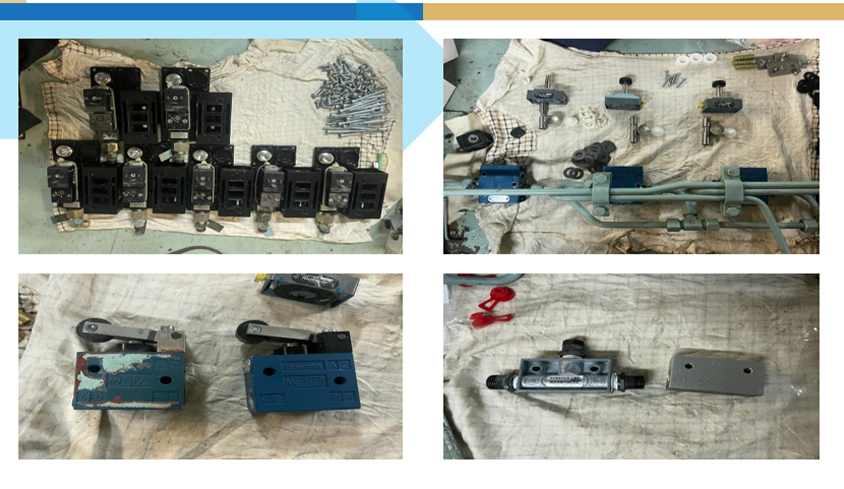

Alpha Lubricator Overhaul

For trouble free operations and to ensure optimized cylinder lubrication, we offer you alpha lubricator overhaul onboard.

Our scope of work includes:

- Check timing and angle encoder arrangement installation.

- Check timing and distance of BCU pick-ups.

- Check and adjust index transmitter.

- Alarm check

- Refilling and replacement (where necessary) of N2 accumulators (both 1.5 bar and 30 bar type).

- Software upgrading (if necessary)

- Visual check of cable connections for fatigues.

- Inspect and overhaul of alpha lubricators.

- System testing onboard.